Laboratories

We offer our customers the highest quality products. We have perfectly equipped laboratories where we perform measurement tests on screws in the M4 – M24 range.

The research and tests carried out in our laboratories not only allow us to confirm the compliance of processes and products, but also enable us to conduct advanced research and development work.

Control and measurement equipment

Our team quality control team performs tests resulting from the ISO 898 standard, which are:

- strength test Rm,

- hardness HV, HRC,

- yield strength test Rp0.2

- stress under test load,

- elongation A%,

- narrowing Z%,

- head solidity/ wedge test,

- impact strength (also at negative temperatures down to -60°C),

- surface integrity according to ISO 6157,

- testing of sets according to ISO 15048,

- analyses determining hydrogen embrittlement ISO 15330,

- upset test to determine material defects.

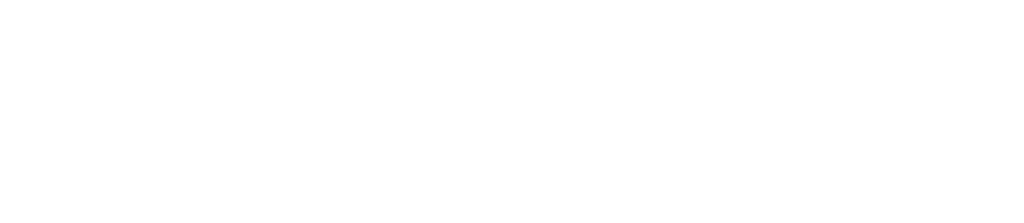

Measurement Laboratory

It has equipment to perform the following tests:

- geometric measurements of products in accordance with drawings or standards, specifications,

- performing analyses of MSA measurement systems,

- performance of machine capabilities, process (SPC),

- Testing the minimum breaking torque MBmin,

- friction coefficient test,

- determining optimal tightening torques for special parts.

Chemical Laboratory

Chemical Laboratory

- chemical composition analysis,

- layer thickness measurement using magnetic, weight and X-ray methods,

- corrosion resistance tests in a salt chamber,

- chemical and physicochemical analyses of various substances,

- tests in a climatic chamber with cycles according to specifications,

- tests of adhesion of paint layers.

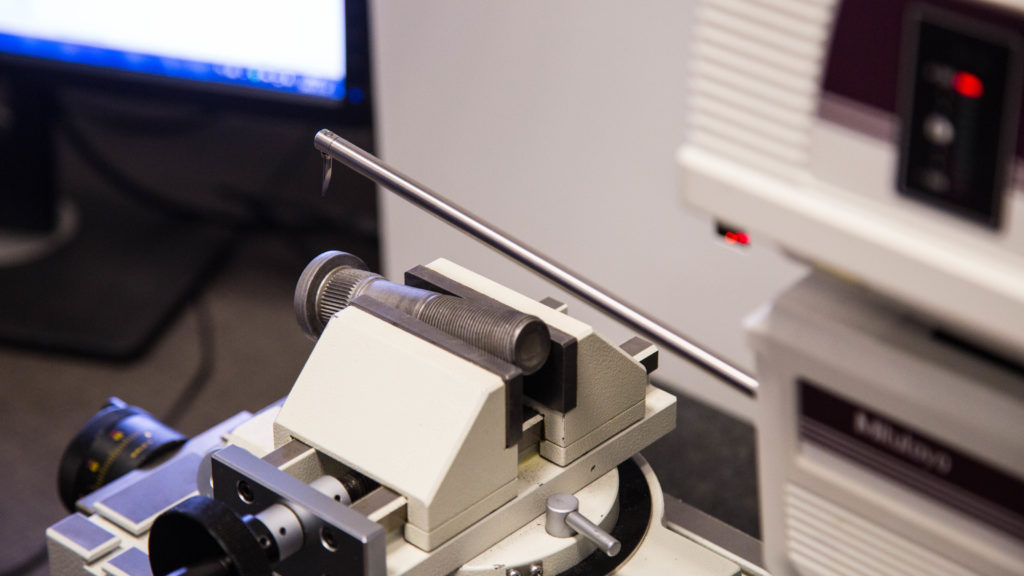

Metallographic Laboratory

We are able to perform complex analyses such as:

- microhardness measurements of core HV10, surface HV0.3,

- microscopic evaluation of steel structures (microstructure testing),

- tests of fiber arrangement, decarburization, material defects,

- qualitative assessment of diffusion layers,

- measurement of layer thickness using the microscopic method according to ISO 1463,

- testing the hardenability of materials.